When it comes to ceiling applications—whether it’s suspending lighting fixtures, decorative panels, signage, or acoustic boards—wire ropes are the invisible heroes that hold everything securely in place. At first glance, choosing a cable might seem as simple as picking a size. But in reality, the wrong choice can compromise both safety and aesthetics.

Why does this matter? Because ceiling applications are overhead installations. A cable failure doesn’t just mean replacing a part—it could lead to falling objects, damaged property, or even injuries. That’s why selecting the correct size, construction, coating, and material is crucial.

This guide will walk you through everything you need to know, from basic concepts like breaking strength and safety factor, to practical comparisons of different materials, structures, and terminations.

1 Cable Size and Strength

Before talking about technical terms, let’s start with a simple question:

How much weight are you planning to hang?

This is the foundation of all cable selection. Once you know the load, two concepts come into play:

Breaking Strength (Minimum Breaking Load, MBL): The maximum force a rope can withstand before breaking.

Safety Factor: A multiplier applied to the working load to ensure safety. In ceiling applications, a safety factor of 5 or more even 10 is typically required.

Minimum Breaking Load (MBL) is usually expressed in Newtons (N) or Kilonewtons (kN), though some manufacturers also list it in kilograms (kg) or pounds (lbs).

Quick conversion:

| 1 kN = 1000 N |

| 1 kg ≈ 9.81 N |

| 1 lb ≈ 4.45 N |

Example:

If a chandelier weighs 20 kg, you should not select a cable rated for only 20 kg. Instead:

20 kg × 5 = 100 kg minimum breaking strength required.

This ensures the cable will hold even under stress, minor impacts, or long-term fatigue.

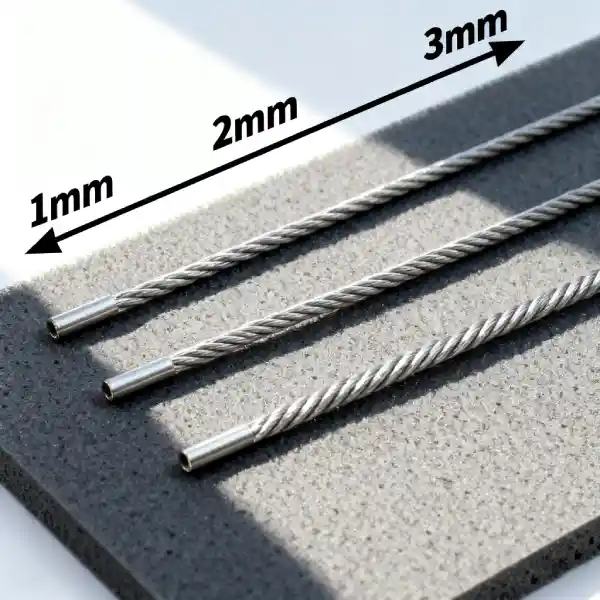

2 Common Wire Rope Sizes for Hanging Applications

Wire rope for ceiling use is usually on the small-diameter side, where strength meets subtle design. Common choices include:

Metric sizes: 1.0mm, 1.5mm, 2.0mm, 3.0mm

Imperial sizes: 1/16” (~1.6mm), 3/32” (~2.4mm), 1/8” (~3.2mm)

Practical recommendations:

1.0–1.5mm (1/16”) → light displays, signage, exhibition frames.

2.0mm (3/32”) → pendant lights, acoustic panels, decorative ceiling elements.

3.0–3.2mm (1/8”) → heavy signs, stage equipment, or large suspended structures.

Smaller cables are discreet and nearly invisible, making them perfect for modern interiors. Larger cables, while more visible, provide extra reassurance when handling heavy loads.

Another option that is becoming increasingly popular in lighting suspension is 1.1mm 1×12 wire rope. Most suppliers can only provide it in short lengths, but at Chuanglihua we are able to supply continuous 3,000-meter reels of 1×12 at this size—ideal for projects that demand both consistency and efficiency.

3 Wire Rope Weight and Structures

Not all cables are created equal. Beyond diameter, the construction pattern affects both strength and flexibility:

1×12construction: made of 12 wires twisted into a single strand. Smooth surface, good balance of flexibility and strength. Popular in lighting suspension.

1×19 construction: 19 wires twisted into a single strand. Very stiff, minimal stretch, ideal for straight-line applications like signage or tensioned suspension. However, less flexible for tight bends.

7×7 construction: 7 strands, each made of seven wires (total 49 wires). A balance between strength and flexibility. Good for general ceiling hanging.

7×19 construction: 7 strands, each made of 19 wires (total 133 wires). Highly flexible, suitable for pulleys, adjustable fixtures, and places where bending is frequent..

In large installations, the rope’s own weight can add up. For example, in stage or exhibition halls with dozens of suspension points, using lighter but equally strong constructions helps reduce overall load.

4 Choosing by Environment

When selecting wire rope, it’s not just about strength and corrosion resistance. Ceiling applications are often visible, so aesthetic appeal and how well the cable blends with the space also matter. That’s why choosing the right finish is important.

4.1 Galvanized Wire Rope

Hot-dip galvanized: the rope is dipped into molten zinc, creating a thick protective layer. It looks a bit rougher but resists rust very well—great for semi-outdoor or long-term use.

- Thicker zinc coating, higher corrosion resistance. Best for semi-outdoor or long-term use.

Electro-galvanized: the zinc is applied by an electric current, giving a smooth, shiny finish. It’s less resistant outdoors but cost-effective and neat-looking indoors.

- Smooth surface, lower cost. Suitable for indoor lighting or decorative panels.

At Chuanglihua, whether you need hot-dip or electro-galvanized, we can customize the zinc coating thickness according to your project’s requirements.

4.2 Stainless Steel Wire Rope

304 stainless: Excellent for general indoor environments. Strong, corrosion-resistant, widely used in lighting and decoration. See more about 304 stainless steel wire rope.

316 stainless: Superior resistance to salt and humidity, recommended for coastal regions, swimming pools, or high-humidity areas. Learn why 316 stainless steel wire rope is preferred in marine applications.

4.3 Coated Wire Rope (PVC, PE, Nylon)

Coating adds both protection and aesthetics:

Prevents scratches and injuries when handling.

Provides extra corrosion resistance.

Available in colors: black (for stage and exhibitions), transparent (for minimal visual impact), or custom colors to match interiors.At Chuanglihua, we can tailor the coating material, thickness, and color to match your specific needs.

Example: A transparent PVC-coated 2mm cable (total coated diameter ~3mm) is often used in modern pendant lighting to make the rope nearly invisible, while black coating is popular in theaters to blend with the background.

5 Rope Terminations: The Overlooked Factor

A wire rope is only as strong as its end fitting. Even the best cable can fail if the termination is weak or poorly installed.

Common types include:

Loops with ferrules → simple and cost-effective.

Thimbles → prevent wear at the loop’s eye, ideal for heavier loads.

Swaged fittings → permanent and strong, often used in architectural applications.

Adjustable cable grippers → widely used in ceiling suspension for easy adjustment of height and angle.

Each termination should be chosen according to both the rope type and the application environment. For example, stainless steel ropes should be paired with stainless steel fittings to avoid galvanic corrosion.

6 Conclusion

Choosing the right wire rope for ceiling applications is more than just picking a size—it’s about balancing safety, functionality, and design.

- Start with the load of your stuff.

- Apply the correct safety factor.

- Select the right construction and size(1×19, 7×7, 7×19).

- Match material and coating to the environment.

- Never overlook proper terminations.