Many customers often ask: “What grade of wire rope do you supply?”

It’s a fair question—but here’s the thing: grade is only one part of wire rope quality—but not the whole picture. Wire rope quality is far more than a number on a datasheet. If you only look at grade, you might miss the factors that really matter for your application.

1 What Does “Grade” Mean?

In wire rope, “grade” usually refers to the tensile strength level of the steel wires—commonly 1770 MPa, 1960 MPa, 2160 MPa or some others.

It’s important to note:

Grade is a material property. It indicates the inherent strength of the steel wires.

To calculate the theoretical strength of a single wire, you need both the grade and the wire diameter.

A few clarifications:

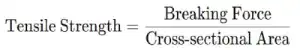

Grade measures the strength of the steel itself, not the rope. Grade tells us the tensile strength level of the steel wire — how much tensile stress it can withstand before breaking.

Note: Tensile strength is not the same as hardness

The breaking strength of the rope ≠ sum of all wires’ strength. Because of the rope’s geometry (how the wires are twisted and layered), the overall rope strength is reduced by a conversion factor known as the “rope efficiency factor.” For most constructions, efficiency ranges from about 0.85 to 0.95. Example: If the combined strength of all wires is 1000 N, the actual rope strength may be 1000N × 0.85 = 850 N.

Minimum breaking load (MBL) is the standardized value representing the rope’s maximum tensile capacity. But even this is not the safe working load (SWL)—in real applications, you must apply a safety factor (commonly 4:1 to 10:1, depending on industry).

Control cable applications (brake, throttle, clutch): usually 4:1–5:1.

Hanging or suspension applications: often 6:1–7:1, since failure could lead to accidents.

So yes, grade matters—but it doesn’t tell you whether the rope will perform well in your specific application.

2 Why Grade ≠ Quality

A high-grade rope is not automatically a high-quality rope. Different industries have different needs:

- Control cables (brake, clutch, throttle): These ropes must endure constant bending and fatigue. Flexibility and fatigue resistance matter more than just strength.

- Suspension & decorative hanging: Here, straightness and corrosion resistance are key. Even the highest grade wire rope will fail quickly if the zinc coating is poor.

- Seals (one-time wire rope seals): Tensile strength is important.

- Gym and fitness cables: Smooth surface finish and durability are vital. A high-grade rope with burrs or roughness could damage pulley systems and cause accidents.

Conclusion: Quality is not one-dimensional. It’s about the right balance of strength, flexibility, surface condition, coating, and consistency—based on the application.

3 Other Key Indicators of Wire Rope Quality

| Indicator | Why It Matters | Example / Application |

|---|---|---|

| Flexibility | Inversely related to strength: higher strength → less flexibility; more flexible → lower strength. | Control cables require flexibility to withstand continuous bending. |

| Corrosion Resistance | Zinc coating thickness and uniformity determine lifespan. | Chuanglihua supplies both electro-galvanized and hot-dip galvanized ropes, with customizable zinc thickness per client’s needs. |

| Dimensional Consistency | Accurate diameter and lay length ensure ropes fit into systems smoothly. Poor consistency causes installation issues, cable jamming, or uneven stress. | Brake cable housings need precise diameters. |

| Surface Finish | Burrs or protrusions affect worker safety and performance. At Chuanglihua, we have a dedicated step where workers manually inspect every meter by hand to guarantee no burrs. | Gym cables, control cables. |

| Fatigue Resistance | The rope’s ability to endure repeated bending cycles. | Brake/throttle cables bend thousands of times during use—fatigue resistance is critical. |

| Production Standards & Testing | Industry standards guarantee reliability. | EN 12385, ASTM A475, ASTM A1023, GB/T 14451, GB/T 20118. |

4 Matching Quality to Applications

Instead of asking only about grade, it’s better to think: what performance does my application need?

Brake / Clutch / Throttle Cables → need flexibility + tensile strength + fatigue resistance. These ropes bend thousands of times, so poor fatigue resistance = early failure.

Seals (wire rope seals) → need tensile strength + tamper resistance. Here, surface smoothness is less important than consistent strength.

Gym Equipment Cables → need durability + smooth surface finish. Burrs or rough surfaces will chew through pulleys or coatings.

Suspension / Hanging Applications → need corrosion resistance + straightness. If ropes aren’t straight, they won’t hang properly, and if the zinc coating is weak, rust will ruin the aesthetics and safety.

5 How to Inspect Wire Rope Quality as a Buyer

Here are some practical steps I recommend to buyers:

- Know the standard (EN, ISO, GB/T, etc.) relevant to your market or application.

- Ask for tensile test reports from the manufacturer.

- Check the rope surface: smooth, uniform, no kinks.

- Verify construction and diameter: 1×19, 7×7, etc., within tolerance.

- Cut a short section → stand it vertically. A well-made rope stands straight without curling.

- Tap or drop a short piece → poor-quality ropes may unravel or fray at the ends.

- Ask about certifications → ISO 9001, production license numbers, or third-party testing. These reflect a mature production system.

6 Conclusion

Grade is important, but it does not equal quality. Real wire rope quality is defined by a balance of tensile strength, flexibility, fatigue resistance, surface finish, and corrosion protection—matched to the needs of your application.

At Chuanglihua, we specialize in small-diameter wire ropes for control cables, seals, gym equipment, suspension and light-duty rigging. For these applications, consistency, flexibility, and durability are every bit as important as tensile strength. That’s why we test every batch and build ropes with performance in mind—not just grade numbers.