When it comes to buying steel wire rope, quality is very important. Whether you’re in construction, maritime, or another industry that relies on these critical components, choosing the right wire rope can make all the difference in your project’s success. But with so many manufacturers out there, how do you ensure you’re getting a product that won’t fail when you need it most?

The challenge lies in comparing products from different vendors, each claiming to offer the best. It’s not just about finding the lowest price; it’s about understanding what makes one supplier’s steel wire rope superior to another. From the materials used to the manufacturing processes employed, every detail counts.

In this guide, we’ll walk you through the essential factors to consider when purchasing steel wire rope, so you can make an informed decision that balances quality, price, and reliability.

1 Checking Supplier Certifications and Reputation

Before you commit to purchasing steel wire rope from suppliers, it’s crucial to verify their certifications and reputation. Certifications like ISO are not just badges—they’re assurances that the supplier adheres to industry standards for quality and safety (Chuanglihua is ISO9001:2015 certificated). A certified manufacturer is more likely to provide products that meet rigorous specifications, giving you confidence in your purchase.

ISO 9001:2015 is the latest version of the internationally recognized standard for Quality Management Systems (QMS). It outlines the requirements organizations must meet to enhance their operational performance and ensure quality in their products and services, thereby improving customer satisfaction. This version places a strong emphasis on risk-based thinking, leadership engagement, and a process approach to establish, implement, maintain, and continually improve a QMS.

But certifications are only part of the story. A supplier’s reputation in the industry can speak volumes about their reliability. Look for reviews from other customers, and don’t hesitate to ask for industry references or case studies. A supplier with a strong track record won’t hesitate to provide evidence of their past successes.

Ultimately, choosing a supplier with the right certifications and a solid reputation reduces your risk. You’ll have peace of mind knowing you’re working with a company that stands behind its products and has a history of delivering high-quality steel wire ropes.

2 Inspecting Material

When evaluating steel wire ropes, one of the first things to consider is the quality of the materials used. Not all steel is created equal, and the type of steel—whether it’s galvanized or stainless—can significantly impact the rope’s performance and longevity. Stainless steel offers excellent corrosion resistance, making it ideal for outdoor or marine environments, while galvanized carbon steel provides superior strength and durability.

Different steel grades will also lead to different tensile strengths. Common carbon steel grades for wire rope are #45 #55 #65. Of course, better materials can be used for specific purposes, such as 62A 72A. You can consult us for bespoke products.

3 Assessing Manufacturing Standards and Processes

Understanding the manufacturing standards and processes behind steel wire ropes is crucial in evaluating their quality. A wire rope’s performance heavily depends on how it’s made, from the initial wire drawing to the final stages of heat treatment, stranding, and roping. High-quality manufacturing processes result in ropes that are strong, durable, and consistent, while subpar methods can lead to weaknesses that compromise safety and reliability.

When dealing with suppliers, don’t shy away from asking detailed questions about their manufacturing processes. For example, inquire about the heat treatment procedures, which are essential for achieving the desired balance of strength and flexibility. Additionally, ask about the wire drawing process, as the precision with which the wires are drawn directly affects the rope’s tensile strength and uniformity.

4 Reviewing Technical Specifications

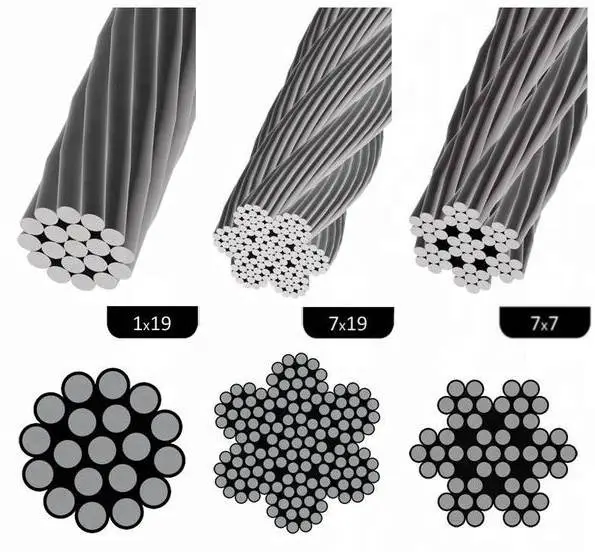

When purchasing steel wire rope, diving into the technical specifications is essential to ensure you’re getting a product that meets your specific needs. Key specs like tensile strength, breaking load, and diameter tolerance are critical indicators of the rope’s performance and suitability for your application.

Start by comparing the tensile strength, which measures the maximum stress the rope can withstand before breaking. This spec is crucial for ensuring the rope can handle the loads you plan to apply. Similarly, the breaking load tells you the point at which the rope will fail under tension, making it a vital factor in safety-critical applications.

Diameter tolerance is another important spec to review, as even slight deviations can impact the rope’s performance, particularly in precision-driven environments. Ensure the rope’s diameter falls within acceptable limits for your specific use case.

By thoroughly reviewing and comparing these technical details, you’ll be better equipped to choose a steel wire rope that not only meets industry standards but also performs reliably in your intended application.

5 Requesting and Evaluating Samples

Before making a final purchase decision, it’s wise to request samples from potential suppliers. Getting your hands on physical samples allows you to assess the steel wire rope’s quality firsthand, ensuring it meets your standards and application needs.

▪ When evaluating samples, start by examining the rope’s flexibility. A high-quality steel wire rope should bend smoothly without kinking, indicating that the wires and strands are well-aligned. Next, check for uniformity in the wire diameter and lay direction; inconsistencies here can signal poor manufacturing practices.

▪ Pay attention to the coating, too. Whether it’s galvanized or stainless, the coating should be evenly applied and free from any visible flaws like cracks or peeling, which could lead to premature corrosion or failure.

▪ With steel wire ropes of the same diameter, the heavier the density, the better the quality.

▪ The stronger and heavier the wire core, the better the support of the outer layer, resulting in a higher quality steel wire rope. Some wire ropes used for bundling on the market do not value the support effect of the steel core, and they use some fiber cores for support, such as 6X19+7FC.

▪ The quality of the steel, in terms of size and strength, matters. The higher the steel grade, the greater the strength and the better the quality of the steel wire rope.

▪ Steel wire ropes that slightly loosen after being cut are of better quality, and those with longer twist lengths are superior to those with shorter twist lengths.

▪ Of course, if conditions permit, it is best to send the samples to a professional third-party agency for testing. The test results are generally objective, fair, and professional.

6 Analyzing Pricing vs. Quality

When purchasing steel wire rope, it’s tempting to focus solely on price, but doing so can lead to costly mistakes down the road. Understanding the relationship between pricing and quality is key to making a smart investment that ensures both safety and performance.

A low price might seem attractive, but it often signals compromises in materials, manufacturing standards, or quality control. Cheaper ropes may lack the durability and strength needed for demanding applications, leading to premature wear, unexpected failures, and potentially dangerous situations.

On the other hand, a higher price doesn’t automatically guarantee superior quality. It’s essential to dig deeper and assess whether the price reflects genuine quality improvements, such as better materials, more rigorous manufacturing processes, or enhanced performance specifications.

To get the best value, compare the pricing of ropes with similar specifications from multiple suppliers. Look for any discrepancies in the specs that might explain price differences, and don’t hesitate to ask suppliers to justify their pricing. In some cases, a slightly higher cost may be worth it for the added peace of mind and longer lifespan of a premium product.

Finally, consider negotiating with suppliers. Many are willing to offer discounts or incentives, especially for bulk purchases, without compromising on quality. The goal is to strike a balance where you get a high-quality steel wire rope that meets your needs at a fair price, ensuring long-term value and reliability.

7 Conclusion

Choosing the right steel wire rope is more than just a purchase—it’s a critical decision that impacts the safety, efficiency, and longevity of your operations. From verifying supplier certifications and reputation to inspecting material quality, evaluating manufacturing processes, and reviewing technical specifications, each step in the assessment process plays a crucial role. By following these guidelines, you’ll be well-equipped to select a high-quality steel wire rope that meets your specific needs.