A few days ago, one of my customers asked me if I had any 3×9 wire rope. I paused for a moment, because honestly, I had never heard of that construction. After a bit more back-and-forth, it turned out what he really meant was 1×12. He was simply describing the structure in his own way, but the terminology was off, and it led to some confusion.

That’s why I decided to write this article. It’s not only for my customer, but also for you and anyone else who wants to avoid that kind of misunderstanding in the future.

What does a wire rope specification actually tell you?

Think of it as the rope’s ID card. A proper specification gives you details such as:

- The rope’s diameter

- How many strands it has

- How many wires are in each strand

- How those wires are twisted together

- What kind of core the rope uses

- The tensile strength of the wires

- The surface finish of the wires

- And the lay direction (the way the strands and wires are twisted)

Once you understand these parts, you can “read” almost any common wire rope spec.

A real example

22 6×36WS-IWRC 1770 B sZ

Let’s break this one down step by step:

- 22 → Rope diameter: 22 mm

- 6 → Six strands (not counting the core)

- 36 → Each strand has 36 wires

- WS → strand construction is Warrington-Seale, a common way of twisting the wires

- IWRC → Independent Wire Rope Core

- 1770 → Wire tensile strength is 1770 N/mm² ( important: this is the strength of the wires, not the rope. The rope’s property is called minimum breaking force, which is the force needed to break the rope.)

- B → B-class galvanized coating

- sZ → Wires in each strand are twisted right (z), and the strands in the rope are twisted left (S)

So the order is basically:

Diameter → Strands → Wires per strand → Construction type → Core → Wire strength → Surface finish → Lay direction.

This example alone can already help someone with a basic understanding describe their needs more accurately and also better understand what a supplier is saying. And if you stick with me through the next section, even if you’re new to wire rope, you might just walk away sounding like half an expert. (Okay, maybe not a full PhD in wire ropes—but close enough!)

Strands

Examples:

- 6×7 → Six strands, seven wires per strand

- 1×12 → One strand, twelve wires

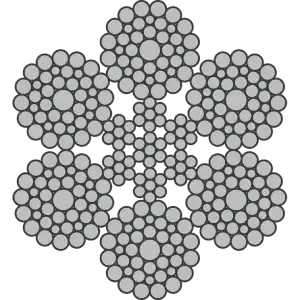

Sometimes you’ll see a three-number format, like 6×6×7. That means: the rope has six outer strands, each outer strand contains six smaller strands, and each small strand has seven wires. Like Russian nesting dolls, but made of steel.

Twisting types of Wires in Strand

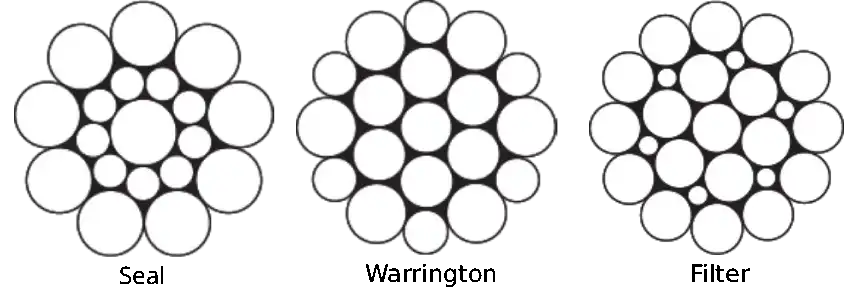

Three of the most common are:

- S (Seale) → Outer layer made of thicker wires for better wear resistance

- W (Warrington) → Outer layer alternates thick and thin wires, giving more flexibility

- F (Filler) → A Warrington layer plus an extra set of thicker wires, so you get both durability and flexibility (but the manufacturing process is more complex, You can also call this the Warrington-Seale type.)

Core types

There are three you’ll run into most often:

- WSC (Wire Strand Core) → A strand serves as the core

- IWRC (Independent Wire Rope Core) → A separate rope serves as the core, giving more strength and durability

- FC (Fiber Core) → Fiber core, not as strong, but it can hold lubricant and helps extend service life

Surface finish

Most wire rope is made from high-carbon steel, which on its own doesn’t resist corrosion. That’s why we add coatings:

- Bright (uncoated)

- B-class galvanized

- A-class galvanized (thicker zinc)

- B-class zinc alloy

- A-class zinc alloy

Right now, the most common zinc coating in the industry is about 40 g/m². At Chunglihua, we can customize the coating thickness if you need something different.

Lay direction

The basic rules are:

- Z → Right lay

- S → Left lay

For single-strand ropes, one letter is enough.

For multi-strand ropes, you’ll see two letters: the first (lowercase) shows the lay of the wires within a strand, the second (uppercase) shows the lay of the strands in the rope.

Example: sZ means wires in each strand are right-laid, and the strands themselves are left-laid.

Do you have any idea how to identify the lay direction in just one second? Please check this article.

Wrapping it up

In this article, we started with a simple example and used it to explain the key parts of wire rope markings. Of course, there are many variations out there, but if you understand these basics, you’ll be able to decode most common specs without trouble.

And next time you’re looking for a rope, you’ll know exactly how to describe it—no more “3×9” moments like the one I had with my customer.

At last the table below shows the standard constructions of our regular products.

| common name | standard name |

|---|---|

| 1X19 | 1X19 |

| 7X7 | 6X7 – WSC |

| 7X19 | 6X19 – WSC |

| 1X12 | 1X12 |

| 1X7 | 1X7 |