Not all of the following points will come up during every inquiry, but understanding and mastering them can enhance our professionalism—whether you’re a buyer or a seller. Sellers can better understand the customer’s needs, and buyers can more accurately describe the steel wire rope they require while also assessing the supplier’s expertise.

1 Product name

I’ve encountered many customers who simply ask for steel wire rope without specifying further. However, steel wire ropes are primarily categorized into two types based on material: stainless steel and carbon steel. If you want stainless steel, make sure to include the word “stainless” in your request.

2 Nominal diameter

e.g., 1X19 2.0mm, etc.

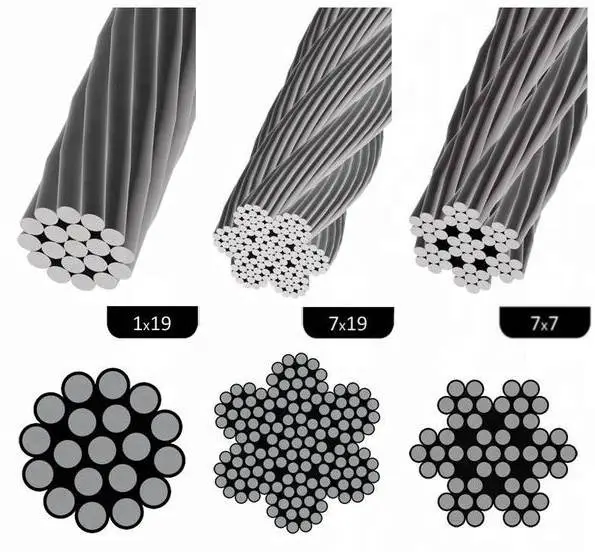

3 Construction (marking code)

e.g., 6X36WS, 6X19S, etc.

The construction and diameter are the most crucial factors. Don’t assume that as long as the diameter meets the requirement, it’s sufficient. Different constructions affect the physical properties of the rope. For instance, a 7×7 2.0mm rope is much more flexible than a 1×19 2.0mm rope.

4 Core type

e.g., steel core (IWRC IWSC), fiber core (FC), etc.

5 Lay direction

e.g., sZ (right regular lay), zS (left regular lay), etc.

6 Wire rope grade,

e.g., 1770MPA, etc.

7 Surface condition of the wire

e.g., bright, electronic galvanized, hot dip galvanized, etc.

Surface treatment is generally aimed at corrosion resistance, so be especially mindful of this if the rope will be used in coastal or humid environments.

8 Quantity

including length, number of coils, weight, etc.

9 Lubrication requirements

including lubrication on strands, wires, and type of grease used

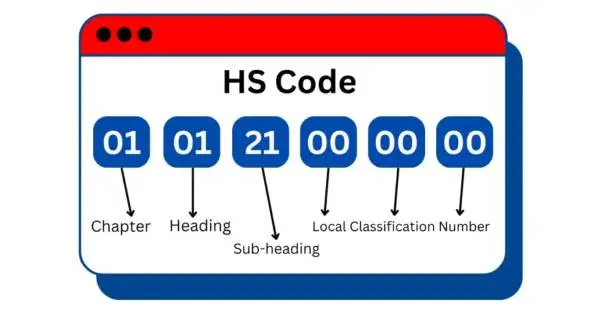

10 Product standards

e.g., GB/T 8918-2006, ASTM 1023 etc.

11 Wire rope application

If you’re unsure about which type of steel wire rope to use, try describing your application to the supplier—you might receive some expert guidance. Chuanglihua is here to help with your inquiries.

12 Packaging

Packaging is an important consideration, especially for steel wire rope. It affects how the product is used by the customer and the overall procurement costs. Take the time to discuss packaging with your supplier—you might gain a lot of valuable insights.

13 Any other special requirements

such as end fittings, cutting service, etc.