When people search “Will galvanized wire rope rust?” they’re usually asking because they saw rust on a rope and want to know whether it’s normal, or whether galvanized steel is a false promise. They want reassurance: If I buy galvanized, will I avoid rust? And if not totally, what can I do to delay or prevent it?

The short answer (for time saving): Yes, galvanized wire rope can rust, but its corrosion resistance is much higher than plain steel rope. Whether it rusts and how fast, depends mostly on the galvanizing quality, the exposure environment, and how well you maintain it.

1 How Does Galvanization Protect Wire Rope?

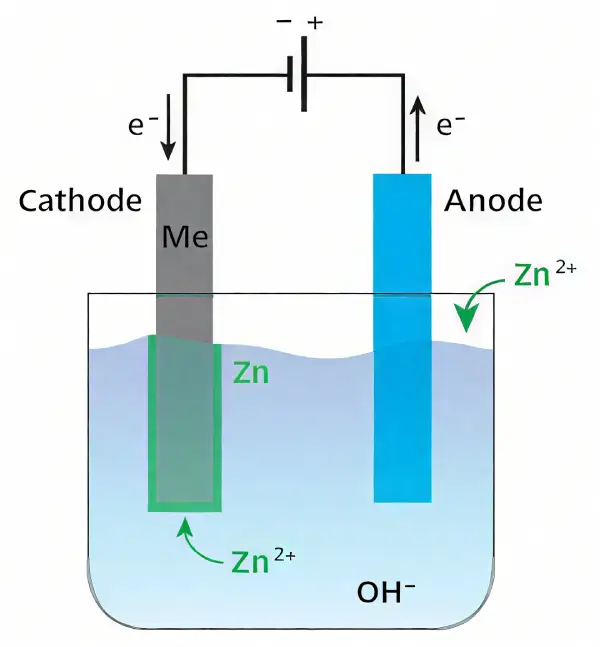

Galvanization works by coating the steel wires with a layer of zinc. This zinc layer protects the underlying steel in two ways:

- Barrier protection: The zinc forms a physical shield, keeping out oxygen, water, and other corrosive elements.

- Sacrificial protection: Because zinc is more reactive than iron, it corrodes first. This “sacrifice” prevents the steel core from rusting until the zinc layer is consumed.

However, this protection isn’t permanent:

- Zinc depletion: Over time, especially in harsh environments, the zinc layer wears away.

- Manufacturing defects: If the galvanizing process wasn’t done correctly (poor cleaning, improper bath temperature, or zinc impurities), you may see cracks, bare spots, or peeling — all of which expose the steel.

- Mechanical damage: Scratches, dents, or abrasion during use can break the zinc coating and trigger local rusting.

For a deeper look at how zinc protects steel, you can check resources from Corrosionpedia or the American Galvanizers Association.

2 The Role of Zinc Layer Thickness

One of the most critical factors is how thick the zinc layer is, and what type of galvanizing process is used. Zinc coating thickness is usually measured in grams per square meter (g/m²):

| Environment / Corrosion Level | Recommended Zinc Coating (Hot-Dip) | Typical Electro-galvanized Equivalent |

|---|---|---|

| Mild indoor, dry studio spaces | ~60–90 g/m² or more (~50–80 μm) | ~5–30 μm |

| Moderate (humid indoor, light outdoor exposure) | 90–200 g/m² (~80–150 μm) | ~30–60 μm |

| Severe (marine/coastal, industrial, acid rain) | ≥200 g/m² (~150–250 μm or more) | Electro-galvanized is often insufficient alone; it needs a thick coating or hot-dip with extra protection |

Note: ASTM A123/A123M is one major standard that defines minimum zinc coating weights for hot-dip galvanizing for wires and steel parts.

- Electro-galvanizing (electroplating) → Zinc is applied via an electric current. Produces thinner and smoother coatings. Better for indoor or low-corrosion conditions. (up to 1200 g/m²).

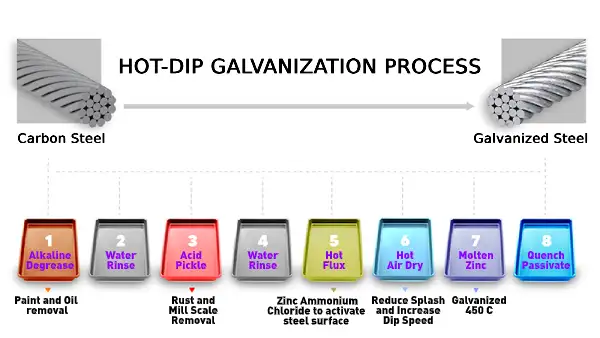

- Hot-dip galvanizing → Submerge steel in molten zinc. Thicker coating, tougher protection, rougher texture. Best outdoors or in harsh/corrosive environments.

Comparing Galvanizing Processes

Electro-galvanizing: smooth, uniform, adjustable coating thickness.

Hot-dip galvanizing: rugged, thicker adhesion, better for heavy-duty outdoor exposure.

At CLH steel wire rope, we provide both and allow customization of zinc type, coating weight, and even plastic coating (different materials, thicknesses, and colors).

3 Choosing the Right Galvanized Wire Rope — What to Look For

To reduce the risk of rust, these are the things you should check when buying:

Coating type and thickness: For indoor, smoother finish and moderate coating; for outdoor / marine, thick hot-dip galvanizing, ideally ≥ 150–200 g/m² or more.

Wire core material: Fiber cores like hemp absorb moisture; better to use synthetic fiber cores or all-metal cores in humid or wet settings.

Rope design (caliber, structure): Fine diameter ropes are less likely to trap water, like construction (e.g., 1×12, 1×19, 7×7, 7×19), which also affects how water and rust spread.

Company quality control: coatings tested, uniformity, batch reports. At Chuanglihua, we can customize zinc thickness for both hot-dip and electro-galvanized; we also offer plastic-coating (PVC/PE/Nylon) with custom thickness/color.

4 Common Galvanizing Defects That Lead to Rust

Even galvanized rope can rust if the coating process has issues:

Process defects: poor cleaning before galvanizing, low zinc purity, improper bath temperature, or unstable equipment.

Residues: acids or salts left on the surface after processing can cause “flash rust.”

Mechanical Damage: to the zinc (scratches, abrasion, cuts, or impacts)

Storage and shipping issues: ropes shipped without proper moisture protection, especially in marine transport, can develop surface rust before they even arrive.

Main Reasons Galvanized Wire Rope Rusts

5 Rust Speed in Different Environments

Here is a summary of real-world data on how quickly galvanized coatings lose zinc or show visible rust, depending on exposure conditions. These help you estimate how long a galvanized wire rope might stay rust-free under your specific environment.

| Environment Type | Typical Corrosion Rate of Zinc Coating | What Causes Faster Corrosion | Implication for Wire Rope Use |

|---|---|---|---|

| Coastal / Marine + Industrial mix | ~ 1.6 µm/year in Los Angeles vs >5 µm/year in Abu Dhabi. (American Galvanizers Association) | High airborne salt, large temperature swings, frequent condensation or dew + high humidity. | A galvanized wire rope used outdoors within ~1 mile of the ocean might show visible rust in 5-7 years unless coated very thickly or maintained carefully. |

| Severe Corrosive Environments | Zinc loss rates in harsh tropical / marine-industrial zones can exceed 80-200 µm/year (Corrosivity category C5-M in ISO / EN / UK standards) for low-carbon steel elements. (galvanizing.org.uk) | Salt spray, pollution, almost permanent moisture or dampness, no protective overcoating. | For such environments, galvanized wire rope needs very heavy zinc coatings, or consider stainless steel, to avoid rust within a few years. |

| Moderate / Coastal (light salt exposure) | Zinc corrosion ~>0.7 to ≤2.1 µm/year, depending on category C3 / C4 classification. (Galserv) | Occasional salt air, moderate humidity, some pollution. | A wire rope with medium-thickness hot-dip galvanization can last perhaps 8-15 years before visible rust, if installation and maintenance are good. |

| Indoor / Dry Environments | Very low zinc loss: ≤0.1 µm/year in very mild indoor atmospheres (ISO category C1). (Galserv) | Low humidity, no salt, minimal moisture cycles. | Visible rust may not appear for many years (even decades). Galvanized rope here is a cost-efficient choice. |

Corrosion rate = average thickness of zinc lost per year. Visible rust tends to appear when steel beneath zinc becomes exposed or when zinc film degrades significantly.

If your installation is near the sea or in a marine climate, expect rust signs maybe in 5-7 years unless you use heavy coating or stainless steel.

For indoor or mild environments, galvanized wire rope can look almost new for 10-20 years or more.

The first year often shows faster zinc loss; if you see the rope in good condition after that period, subsequent corrosion often slows down because a “patina” or zinc corrosion products help somewhat protect the remaining zinc.

6 Galvanized vs Stainless Steel Wire Rope

Galvanized wire rope: better cost-performance balance, strong sacrificial zinc protection, but limited lifespan in aggressive environments.

Stainless steel wire rope: naturally rust-resistant due to chromium content, but costs significantly more.

| Property | Galvanized Rope | Stainless Steel Rope (304 / 316) |

|---|---|---|

| Cost | Lower initial cost; zinc layer protects | Higher cost, but naturally corrosion-resistant |

| Corrosion Resistance | Good, especially with thick zinc and good maintenance, but subject to rust once the zinc layer degrades | Excellent. 316 handles salt and humid environments much better than galvanized. 304 is good in less harsh conditions |

| Appearance | Zinc may dull or stain over time; zinc patina forms | Stainless stays brighter longer, with less visual decay |

| Maintenance | Needs occasional lubrication, inspection, and possible replacement after zinc wears off | Less maintenance, though not entirely zero |

| Life expectancy in coastal/marine environments | With ≥200 g/m² hot-dip and proper maintenance, years of service; otherwise, rust can appear relatively quickly | Much longer life; 316 could last many more years with minimal rust |

A rule of thumb: for decorative use or moderate outdoor projects, galvanized rope is usually enough. For marine or chemical applications, stainless steel might be worth the investment.

7 How to Prevent Galvanized Wire Rope From Rusting

- Choose the right rope

- Select the proper zinc thickness for your environment.

- Avoid fiber cores in corrosive environments; polypropylene (PP) cores are more resistant.

- Install carefully

- Avoid dragging ropes on rough surfaces.

- Prevent sharp bends or heavy impacts that can scratch the zinc.

- Maintain regularly

- Inspect for rust spots, coating loss, and broken wires.

- Apply rope lubricants or protective grease — yes, even galvanized ropes benefit from lubrication.

- Store in dry, ventilated conditions, away from chemicals.

At CLH Wire Rope, every batch goes through lab testing to ensure zinc coating quality. We also hold an ISO 9001:2015 certificate and the new national production license (No. 00002) — a government-recognized mark of quality.

8 Maintenance & Inspection Tips

- Regular inspections are crucial — look for early signs of rust, zinc peeling, or surface damage.

- Even after galvanization, apply protective lubricants during service.

- Store properly: clean coils, a dry environment, and away from corrosive agents.

9 Case Example & Real-World Best Practices

If you hang a light fixture in a coastal hotel lobby, you might specify: hot-dip galvanized rope with ≥ 200 g/m² zinc, stainless 316 fittings, and frequent inspections.

If you use 1×12 structure rope in decorative lighting indoors (low humidity), electro-galvanized or lighter hot-dip may work fine.

Use a rope lubricant—special grease designed for wire rope—to supplement protection, especially around fittings or in bends.

10 Lifespan Estimation & How to Extend It

The lifespan of a galvanized wire rope depends heavily on the environment and maintenance. In mild indoor settings, it might last 10–20 years without serious rust; outdoors or near the ocean under harsh conditions, significant rust might appear in just a few years unless protective measures are strong. Replace ropes when rust has eaten through enough zinc that steel is visibly exposed, or when strength has dropped (broken wires, loose cores).

Lifespan varies from a few years (in marine zones) to decades (in dry areas).

- Inspect regularly: look for peeling zinc, broken wires, and surface rust spots.

- Lubricate often. Even galvanized metal benefits from rust-inhibiting grease.

- Avoid damage: no sharp edges, avoid scraping or rubbing raw metal surfaces.

- Store wisely: dry, well-ventilated, avoid salt exposure or condensation.

Bottom line: galvanized wire rope is highly resistant to rust — but not rust-proof. Its longevity depends on zinc quality, environment, and care.

Conclusion

Galvanized wire rope can and will rust eventually, but carefully chosen products—good zinc type and thickness, proper structure, correct fittings—and regular maintenance can make it long-lasting.

If you expect harsh exposure (salt air, chemicals, extreme humidity), go for heavy hot-dip galvanizing or stainless steel.

Always match your rope choice to the environment, the visual demand, and the safety requirement.