Embarking on the journey of purchasing wire ropes can be daunting, with a maze of terminology to navigate. But fear not! Our comprehensive guide is here to light your way, offering an array of essential terms and definitions to empower you with the knowledge needed to make informed decisions and confidently choose the right wire rope for your needs.

1 Wire

Outer wire: refers to the outermost layer of steel wire in a structure.

Inner wire: typically refers to the steel wires located between the core or center wires and the outermost wires in a structure, serving as an intermediate layer for reinforcement and support.

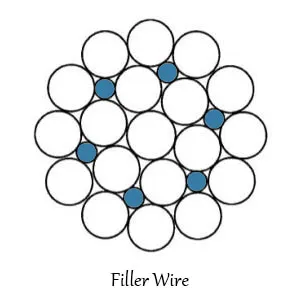

Filler wire: refers to the relatively thin steel wires used in a filling structure to fill the gaps between layers of steel wires, providing reinforcement and stability.

Centre wire: refers to the steel wire positioned at the core or center of a strand or a steel wire rope, providing strength and stability to the structure.

Wire tensile strength: refers to the strength of a steel wire, typically measured in units of Newtons per square millimeter (N/mm²), which can be used to calculate the minimum breaking force of a steel wire rope.

Finish of coating: refers to the state of the surface of a steel wire, which can include a smooth surface (uncoated), a zinc coating, a zinc alloy coating, a copper coating, or other protective coatings.

Mass of coating: refers to the quantity of coating material present per unit surface area of a steel wire, typically measured in grams per square meter (g/m²). This measurement indicates the density or thickness of the coating applied to the wire surface.

2 Strand

refers to a group of steel wires twisted or braided together to form a single unit within a steel wire rope. It is one of the basic components of a wire rope, with multiple strands typically twisted around a core to create the final rope structure.

Different types of strands have varying characteristics such as tensile strength, flexibility, corrosion resistance, etc. Therefore, different strands are utilized in different environments. Common strand structures include single lay strand, seale lay strand, warrington lay strand, filler lay strand, and compacted strand.

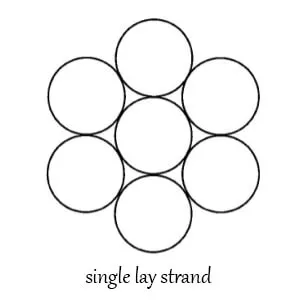

Single lay strand: A strand composed of only one layer of steel wires twisted together to form the unit within a steel wire rope.

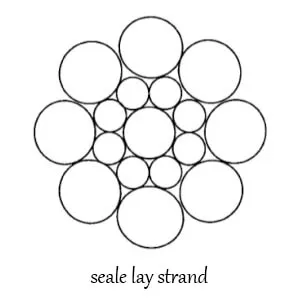

Seale lay strand: Refers to a type of strand in which two layers of steel wires with the same number of wires are laid parallel to each other to form the unit. This construction provides balance and symmetry to the strand.

Warrington lay strand: Refers to a type of strand construction in which the outer layer consists of alternating thick and thin steel wires, and the number of outer wires is twice the number of inner wires in a parallel configuration.

Filler lay strand: The number of outer wires is twice that of the inner wires, and there are filler wires in the gaps between the two layers of wires.

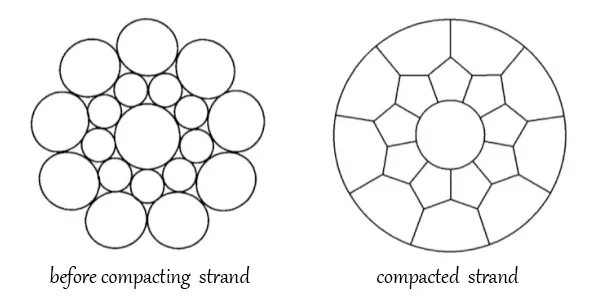

Compacted strand: A type of strand that has undergone deformation processes such as drawing, rolling, or forging, resulting in changes to the shape and dimensions of both the individual wires and the strand itself.

2.1 Terms about strand

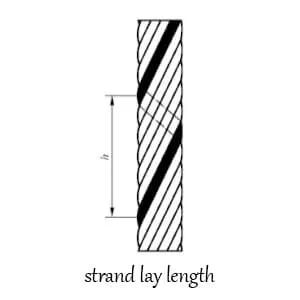

Strand lay length: the distance along the axis of the strand that one strand element (wire or group of wires) advances in one complete turn around the strand axis. It is typically represented by “h,” in lowercase.

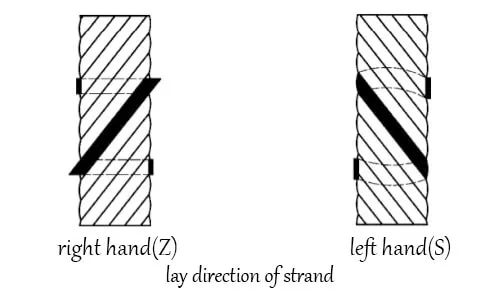

Lay direction of strand: the direction in which the outer wires of a strand are twisted around the axis of the strand. This can be either left-hand lay (S) or right-hand lay (Z), depending on the direction of the twist.

3 Core

The core of the rope is the central part of the steel wire rope, mainly divided into metal core and fiber core. Its main functions are to provide support, reduce pressure between strands, and in the case of fiber core, lubricate, prevent corrosion, and store oil.

According to the material, there are two main types of steel wire rope cores:

Fiber Core (FC): Usually made from natural or synthetic fibers such as sisal, hemp, cotton yarn, flax, nylon, etc. The fiber core can store more lubricant, providing better lubrication for the steel wire rope. It is suitable for light loads and relatively light-duty environments such as telecommunications and agriculture.

Steel Core (WC): Steel core is more abrasion-resistant compared to fiber core, suitable for high-strength, heavy-duty working environments such as large cranes, shipbuilding, and the steel industry. In the notation of steel wire ropes, WC represents steel core. Depending on the structure of the steel core, it can be further divided into wire strand core (WSC) and independent wire rope core (IWRC).

4 Lubricant and corrosion inhibitor

The substances are applied to steel wire ropes to reduce friction between wires, and strands. Preventing rust or corrosion, and enhancing the overall durability and lifespan of the rope. These substances help maintain the smooth operation of the wire rope and protect it from environmental elements such as moisture and oxidation.

There are three common types of lubricants and corrosion inhibitors:

Rope lubricant: Primarily reduces internal friction within the steel wire rope and prevents wire corrosion.

Impregnating agent: Added to natural fiber cores to prevent rot.

Preservation agent: A form of protective agent used to safeguard fiber cores and fill gaps within the steel wire rope.

5 Rope

A steel wire rope is a structure formed by at least two layers of wires wrapped around a central wire or multiple strands twisted around a core. It is generally divided into multi-strand rope (stranded rope) and single-twist rope (spiral rope).

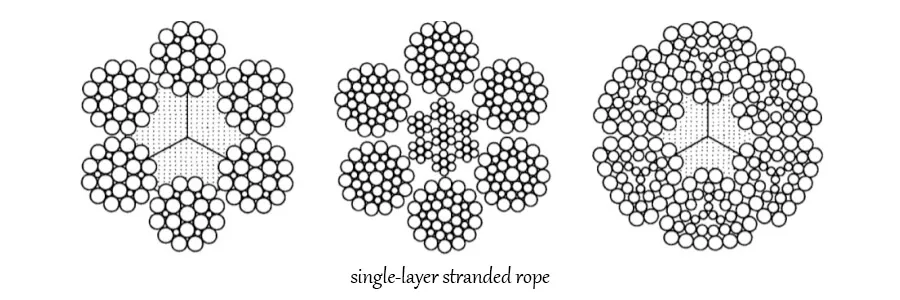

5.1 Stranded rope

Multiple strands are twisted around a core or a central wire to form one or more layers of steel wire rope. Such as our 7×19 and 7×7 galvanized steel wire rope.

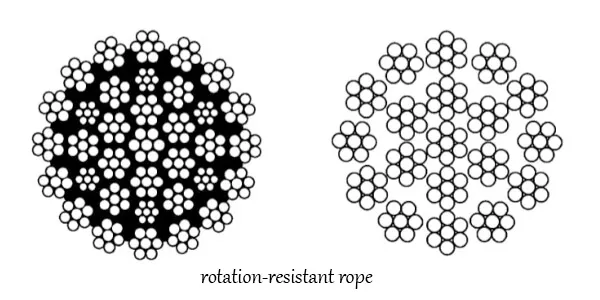

Rotation-resistant rope: is a multi-strand rope capable of reducing torque or twisting when under load. It is typically composed of at least two layers of strands twisted around a steel strand core or fiber core in a spiral manner, with the outer layers twisted in the opposite direction to the adjacent inner layers. Anti-rotational steel wire ropes are commonly used in the lifting and hoisting industries.

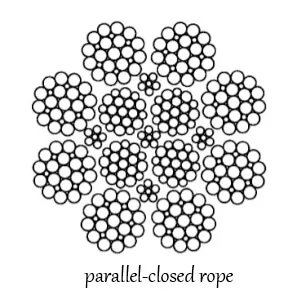

Parallel-closed rope: twisting two or more layers of strands around a core, such as a strand or a fiber core, in a parallel manner. This construction results in a rope where the strands are tightly arranged side by side, providing enhanced strength and durability.

Compacted strand rope: a multi-strand steel wire rope where the individual strands have undergone a process of compacting through methods such as drawing, rolling, or forging before being formed into the rope.

Compacted (swaged) rope: a multi-strand steel wire rope that has undergone a process of compaction after being formed into a rope.

Unlike compacted strand rope, where the individual strands are compacted before being formed into the rope, compacted rope refers to the entire rope being compacted after its formation.

5.2 Spiral rope

Spiral rope is constructed by twisting at least two layers of wires around a central round wire, a combination of strand cores, or parallel-laid strands in a spiral manner. Additionally, in a spiral rope, at least one layer of wire is twisted in the opposite direction to the outer layers.

This construction provides the rope with enhanced flexibility and resistance to torque. The 1×19 galvanized steel wire rope we produce belongs to the category of single-twist steel wire ropes.

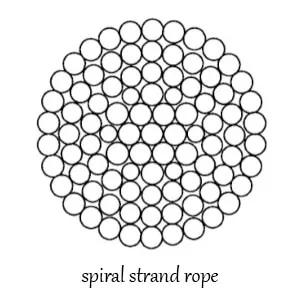

Spiral strand rope: a type of single-strand steel wire rope made solely from round wires twisted together in a spiral configuration.

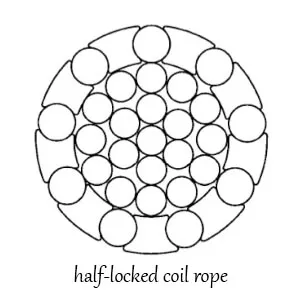

Half-locked coil rope: the outer layer is constructed with alternating half-locked wires ( such as an “H” shape), and round wires.

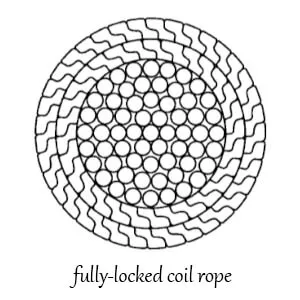

Full-locked coil rope: the outer layer consists entirely of fully locked wires (often shaped like the letter “Z”).

5.3 Terms about wire ropes

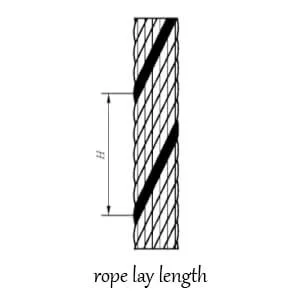

Rope lay length: the distance along the axis of the rope that one strand advances in one complete turn around the rope axis. It is typically represented by “H,” in uppercase.

Lay direction of rope: the direction of the helical twist of the strands and wires within the wire rope.

For spiral ropes, the method of determining the lay direction is the same as for strands. However, for stranded ropes, the representation of lay direction is typically categorized into various types:

- Ordinary lay or Regular lay(sZ zS): Strands or wires are twisted in the opposite direction to the direction of the rope’s twist.

- Lang lay(zZ sS): Strands or wires are twisted in the same direction as the direction of the rope’s twist.

- Alternate lay(aZ aS): Strands or wires within the rope have alternating lay directions.

- Contra lay: Strands or wires are twisted in the opposite direction to the lay direction of the rope.

- Spring lay: A specific type of lay designed to increase flexibility and reduce torque in the rope, often used in specialized applications.

Typically, the lay direction of a steel wire rope is represented by two letters. The first letter, in lowercase, indicates the lay direction of the strands, while the second letter, in uppercase, indicates the lay direction of the steel wire rope.