Choosing the right steel wire rope is critical to ensuring safety, durability, and efficiency across a wide range of applications.

1 Selecting Steel Wire Rope Based on Temperature

Fiber core steel wire ropes should only be used at temperatures below 100°C. Steel core ropes can withstand temperatures up to 200°C. When used in low-temperature environments, choose wire ropes with better grease performance. Do not use high-carbon steel wire ropes at temperatures above 400°C.

Steel wire ropes lose strength at temperatures above 100°C (a 10% loss from 100°C to 200°C, 25% from 200°C to 300°C, and 35% from 300°C to 400°C), so the load on the rope must be reduced during use. Grease loss accelerates at temperatures exceeding 60°C, reducing the wire rope’s lifespan. Special lubricants are required for temperatures above 200°C.

2 Selecting Steel Wire Rope Based on Corrosion

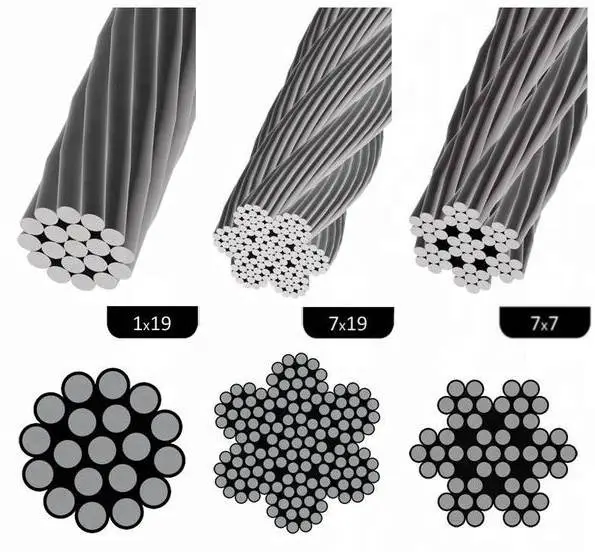

Steel wire ropes made from fewer, thicker wires offer better corrosion resistance compared to those made from many thinner wires. Consider choosing ropes with the largest possible wire diameter while ensuring a balance with bending fatigue performance.

Suppose corrosion is expected or known to be the primary cause of wire rope failure. In that case, it is recommended to use galvanized wire ropes or other ropes with good corrosion-resistant properties.

3 Selecting Steel Wire Rope Based on Wear and Tear

When wear is the primary cause of wire rope failure, consider selecting ropes with thicker outer wires, while also considering bending fatigue performance. Under frictional conditions, using same-direction lay ropes or compacted strand ropes can be beneficial.

4 Selecting Steel Wire Rope Based on Drum Crushing

Fiber core multi-strand ropes should not be used on devices with multi-layer winding. Steel core ropes and compacted strand ropes have better resistance to crushing and deformation.

5 Selecting Steel Wire Rope Based on Bending Fatigue

Wire ropes made from many thin wires offer better fatigue performance compared to those made from fewer thicker wires. Choose wire ropes with a higher number of thinner wires, while ensuring a balance with wear resistance and corrosion resistance.

6 Selecting Steel Wire Rope Based on Impact

Steel core wire ropes and compacted strand ropes offer impact resistance.

7 Selecting Steel Wire Rope Based on Rotation

Choose anti-rotation wire ropes, or pair left-hand lay and right-hand lay ropes for use.

When selecting a wire rope, you can refer to the comparison chart of fatigue resistance and wear resistance of different wire rope structures (X diagram). The ropes in the middle region of the chart offer both good fatigue resistance and wear resistance.