1 What Is Wire Rope Lay Direction?

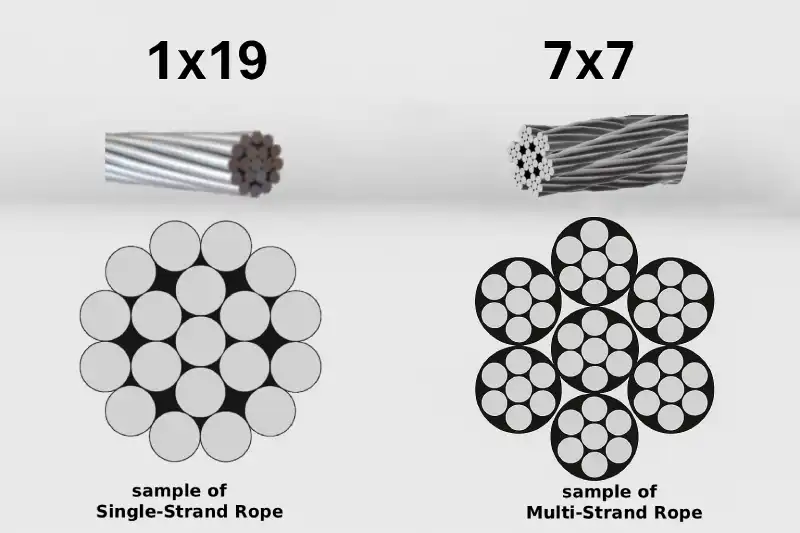

The lay direction of a wire rope refers to two things:

- The way the outer wires inside each strand are twisted around the strand core.

- The way the outer strands are twisted around the rope’s main core.

For single-strand ropes, it simply describes the direction in which the wires are twisted. For multi-strand ropes, it shows both the strand lay and the overall rope lay.

2 Types of Wire Rope Lay Direction

There are three main types of lay direction in wire ropes, and each has its own variations depending on whether the twist goes left or right.

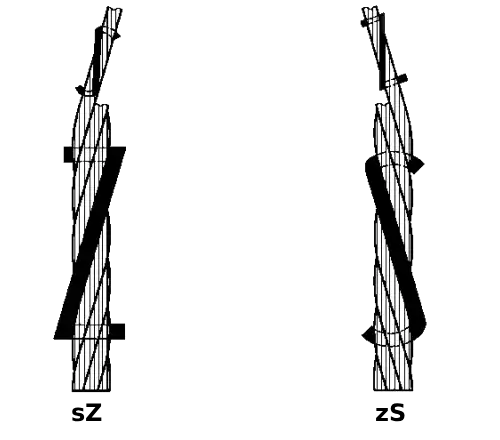

2.1 Ordinary lay

In an ordinary lay rope, the outer wires are twisted in the opposite direction of the strands. This makes the rope more stable and less likely to untwist under load.

- sZ (Ordinary Lay, Right) → The strands are twisted to the left (S), but the rope is closed to the right (Z). The strand lay is opposite to the rope lay. This is the most common and stable type.

- zS (Ordinary Lay, Left) → The strands are twisted to the right (Z), but the rope is closed to the left (S). The strand lay is opposite to the rope lay. Has the same properties as Right Regular Lay.

You can think of ordinary lay as the “default” choice for heavy-duty applications where structural stability is more important than flexibility.

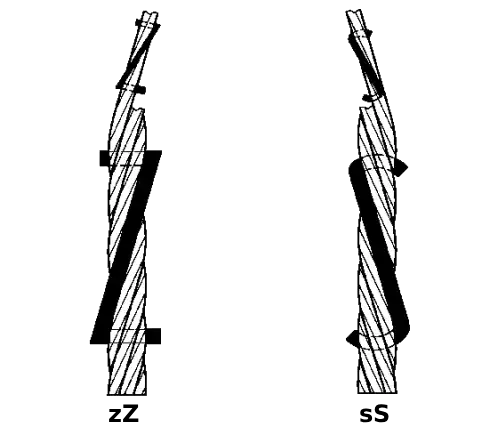

2.2 Lang lay

In a Lang lay rope, the outer wires and the strands are twisted in the same direction. This construction gives the rope better flexibility and surface wear resistance, making it ideal for ropes that bend often around sheaves or pulleys.

- sS (Lang Lay, Right) → Both the strands and the rope are twisted to the left (S). The strand lay is the same as the rope lay. Has the same properties as Right Lang Lay.

- zZ (Lang Lay, Left) → Both the strands and the rope are twisted to the right (Z). The strand lay is the same as the rope lay. More flexible and abrasion-resistant but prone to spinning

A Lang lay rope will feel more flexible in your hand, and it tends to last longer in applications where the rope is constantly moving over wheels or drums.

2.3 Alternate lay

Alternate lay ropes are a hybrid, where the outer strands alternate between different lay directions. For example, one strand might be left-hand, the next right-hand, and so on. This design aims to balance flexibility and stability.

- aZ ((Alternate Lay, Right)→ Adjacent strands in the rope are twisted in opposite directions (some left, some right), and the rope is closed to the right (Z). Designed to minimize rotational tendency.

- aS (Alternate Lay, Left) → Adjacent strands in the rope are twisted in opposite directions (some left, some right), and the rope is closed to the left (S). Designed to minimize rotational tendency.

Alternate lay ropes are less common, but they’re useful when you need the benefits of both ordinary and Lang lay in one rope.

| Lay Types | Alternative Notation | Symbol&Abbreviation(s) | Strand/Rope Direction | Key Features |

|---|---|---|---|---|

| Ordinary Lay | Regular Lay Cross Lay | sZ (RLR) zS (LLR) | Opposite | Stable, resists untwisting,doesn’t kink easily. |

| Lang Lay | Parallel Lay | sS (LLL) zZ (LLR) | Same | Flexible, good wear resistance |

| Alternate Lay | Mixed Lay | aZ aS | Alternating | Combines the advantages of both |

After reading the above, can you think of the easiest way to identify the lay direction? In fact, it only takes three steps:

- Check whether the rope is single-stranded or multi-stranded.

- Confirm the strand direction.

- Confirm the rope direction.

Just keep in mind: strand directions are written with lowercase letters at the front, while rope directions are written with uppercase letters at the back.

3 Why Are There Different Lay Directions?

Lay direction is all about engineering performance and safety:

- Balancing torque to prevent rope spin

If every rope were twisted the same way, they’d want to rotate under load. By alternating lay directions—like using a left-lay and a right-lay rope together—engineers can cancel out torque and keep loads stable. - Flexibility vs. structural stability

- Elevators and cable cars → Lang lay ropes bend smoothly and last longer on sheaves.

- Cranes and mining hoists → Ordinary lay ropes stay tighter under heavy, shock loads.

- Compatibility with drums and sheaves

The rope must “match” the winding direction of the drum. A mismatched rope can climb, kink, and wear out prematurely.

4 Lay Direction in Different Industries

- Control cable producers (brake, throttle, clutch cables) → Lay direction isn’t a big factor; cable performance depends more on diameter and coating.

- Sealing wire rope manufacturers → Focus is on anti-tamper and anti-rust features, not lay.

- Lighting manufacturers (chandelier suspensions) → Small decorative ropes are used in short lengths, so lay direction is rarely considered.

- Hoists and lifting systems → Lay direction is critical for safety, torque balance, and long-term reliability.

5 Where Lay Direction Really Matters

In summary, lay direction is critical for:

- Cranes and lifting equipment (to prevent spinning loads).

- Elevators and cable transport systems (for smooth bending and reduced wear).

- Mining and heavy-duty hoists (for maximum stability under shock loads).

For lighter-duty applications—like control cables, seals, or lighting—other factors (diameter, coating, flexibility) matter far more than lay direction.

6 Final Takeaway

Wire rope lay direction may sound like a small detail, but it’s a key factor in how a rope behaves under load. Ordinary lay, Lang lay, and alternate lay each have their own strengths, and the “right choice” depends on your application.

If you’re in industries like lifting, hoisting, or elevators, you’ll need to pay close attention to lay direction. But for many light-duty uses, you can safely focus on other rope properties without worrying too much about it.